One million bags of Brussels sprouts being packed in Aberdeen – by robots

The firm packs more than 100,000 products every day for the major supermarkets.

An Aberdeen company will pack one million bags of Brussels sprouts this month as the festive season kicks in.

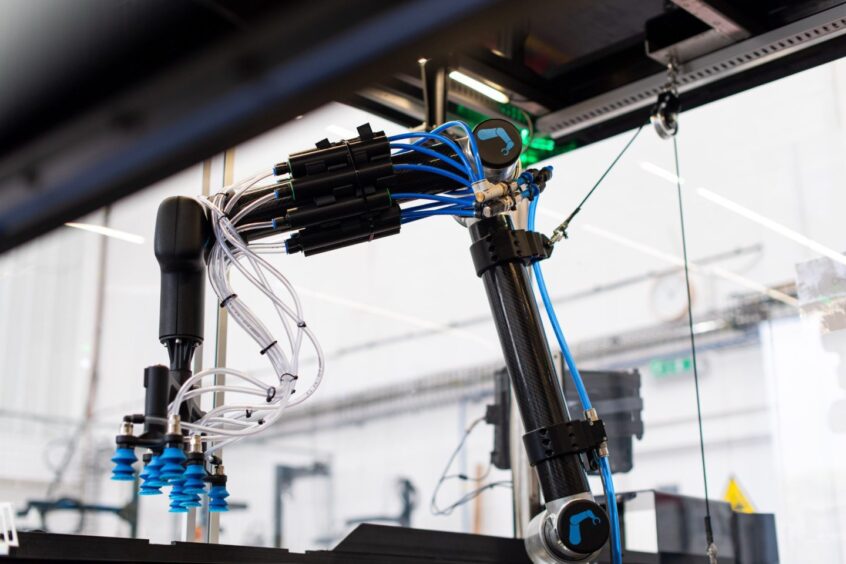

But it isn’t humans packing the sprouts for Christmas – but high-tech robots based in Tullos.

Leap AI has seen demand for its packaging services soar. Founder and chief executive Ben Stuart said the business is currently packing more than 100,000 products every day for all major supermarkets.

The business, which specialises in AI-enabled robotics for food companies, moved to new premises earlier this year, trebling its footprint.

Brussels sprouts demand

The firm designs and builds robotic systems from the ground up while developing their own software – in a move it says provides a simpler, more cost-effective option for robotic automation.

Ben, who started the business in 2018, said the business is packing around 70% more products per month than this time last year.

It is expected to hit three million items by the end of March next year.

Ben said: “We’ll pack a million bags of Brussels sprouts this month.

“And right now the system is going gangbusters 24 hours a day.

“We should pack well over two million items in December due to the peak Brussels sprouts season.

“Every month we pack about a million bags of salad for supermarkets.”

Leap AI product growth

Its first product, the PikPak solution, was launched in 2022.

It is capable of packing a wide range of products at effective speeds and is compatible with a wide range of trays and boxes including those used by all key supermarkets and online retailers.

The company has driven a major push into fresh food and accelerating adoption of its PikPak.

Ben said: “We’ve doubled down on the fresh produce industry – that’s where the need for our product is greatest.

“The real complexity is coping with real-world variability at a price that can compete with minimum-wage labour.”

Delivering reliable performance in challenging packhouse environments has been a major technical focus.

“These systems may need to run up to 24 hours a day,” he said.

“Achieving that reliability, day in and day out, has been a huge challenge – but one the team have really stepped up to.”

Steady staff numbers

Leap AI employs around 30 staff, and while the business has made “some really strong hires” this year, headcount is expected to remain stable as the company scales and looks towards exporting.

Its team includes robotics engineers, machine learning specialists, software developers, 3D printing specialists and data specialists.

Last year Leap AI received a £7.9 million investment, led by £3.5m from the Scottish National Investment Bank and funding from Mercia Ventures and WA Capital.

The funding helped support growth and the firm’s move to a new facility on Greenbank Road in Tullos, which has tripled workshop space and doubled office capacity.

Its robotics and operations teams are now based there, while its software hub in Edinburgh is expanding.

Leap AI bright future

Ben said the past year had marked “a huge step forward” for the business – professionally and personally.

“I still get excited when I find a bag of salad in Tesco in Banchory that’s been packed by one of our robots, he said.

“What’s been really exciting is seeing people who’ve been with us since the very early days now leading key functions. In the early days of a start-up you wear every hat – watching the team step forward has been the biggest highlight.

“I feel more excited about what we’re doing more than ever before.”

[Source: Press and Journal]

/file/attachments/orphans/taku-transport_666718.jpg)